6307 High Temperature High Speed Hybrid Ceramic Ball Bearing

Basic Info

Model No.: 6307

Product Description

Model NO.: 6307 Aligning: Non-Aligning Bearing Rows Number: Single Material: Bearing Steel Precision: P5 (ABEC-5) Friction: Z2V2 Specification: CE, RoHs, SGS, ISO9001 HS Code: 848210200 Contact Angle: 45° Separated: Unseparated Load Direction: Radial Bearing Quality Control: ISO/Ts 16949 Radial Clearance: C3 Trademark: W&M Origin: Zhejiang, China  Features:

Features:

1. Low density. As the rolling body density decreases, high-speed operation of its centrifugal load is also reduced, which can work at higher speed.

2. Moderate elastic modulus. Elastic modulus is too large due to stress concentration and reduce the bearing capacity of the bushing.

3. Thermal expansion coefficient is small. Reduce the sensitivity to temperature changes, so that the bearing operating temperature range is wider.

4. High compressive strength. High compressive strength is the need for high stress for rolling bearings.

5. High hardness and high toughness. These two properties combine to achieve better surface roughness; and can prevent external particles and shock damage.

6. Good anti-rolling contact fatigue and has a peel failure mode.

7. Special occasions should have high temperature, corrosion resistance and stability.

Applications:

The ceramic material has low density, medium elastic modulus, thermal expansion coefficient is small, high hardness, high temperature, corrosion resistance, non-magnetic, etc., to silicon nitride ceramic ball for the rolling body of Ceramic Ball Bearings can significantly improve the bearing contact fatigue life, Has greatly expanded the application of rolling bearings, has been widely used in a variety of high-precision, high-speed machine tools, automobiles, racing, subway, motor, aero engine, petrochemical machinery, metallurgical machinery and other fields

About us:

We're the professional manufacturer of Deep Groove Ball Bearings with 20 years' experience in China. We focus on producing good quality with high precision and low friction ball bearings. The product is designed to support customers in Agricultural, Distribution, Electrical, Fluid, Industrial Transmission, Material Handling, Textile Industry and etc. For many applications, WM standard bearing will meet customer performance expectations.

Delivery:

Sample Date : 3~7 days

Production Date : 30 days after receiving advanced payment.

Shipping : By express (TNT/ FedEx / DHL / EMS ) or By Sea

Payment Term: A. 30% T/T In Advance , 70% T/T paid against B/L copy at sight

B. 100% L/C at sight

Packing : Industrial Package or According to customer's requirement

SGS/CE/ISO9001 CERTIFICATE

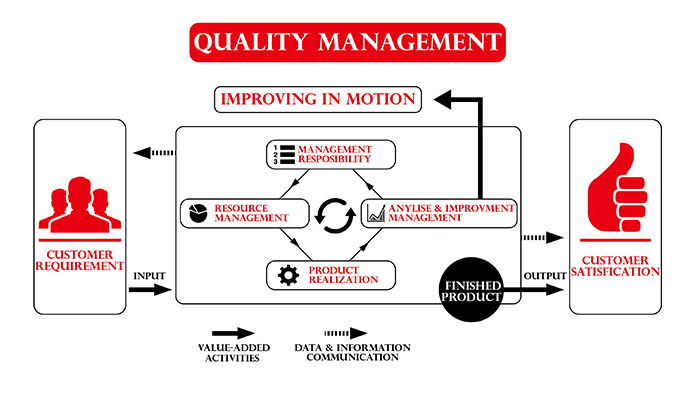

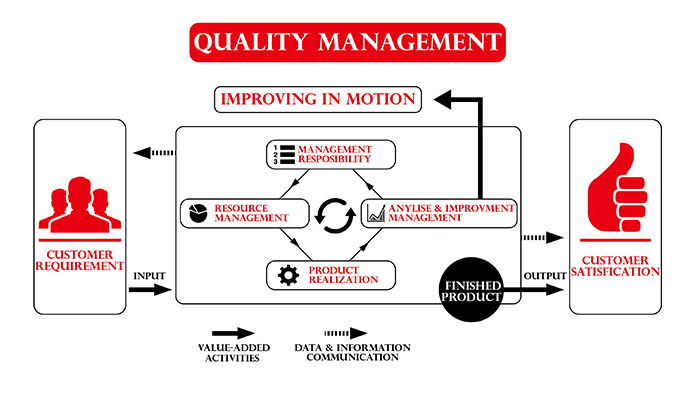

HOW TO SATISFY CUSTOMERS?

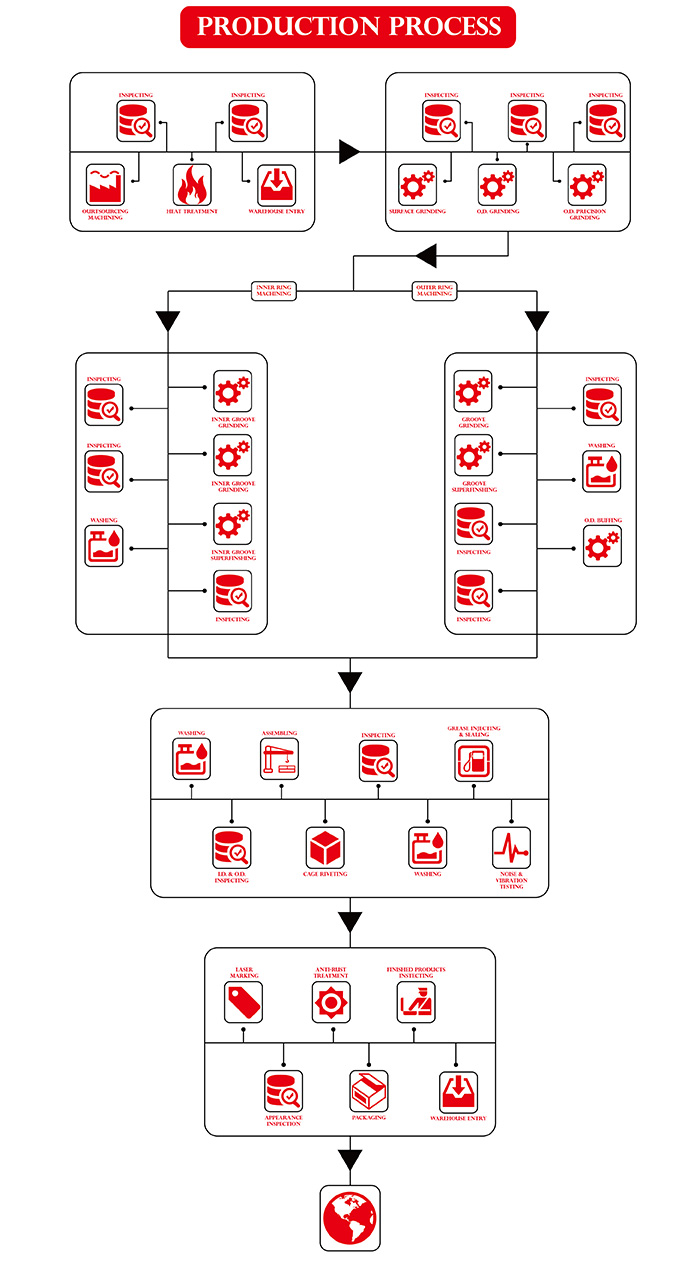

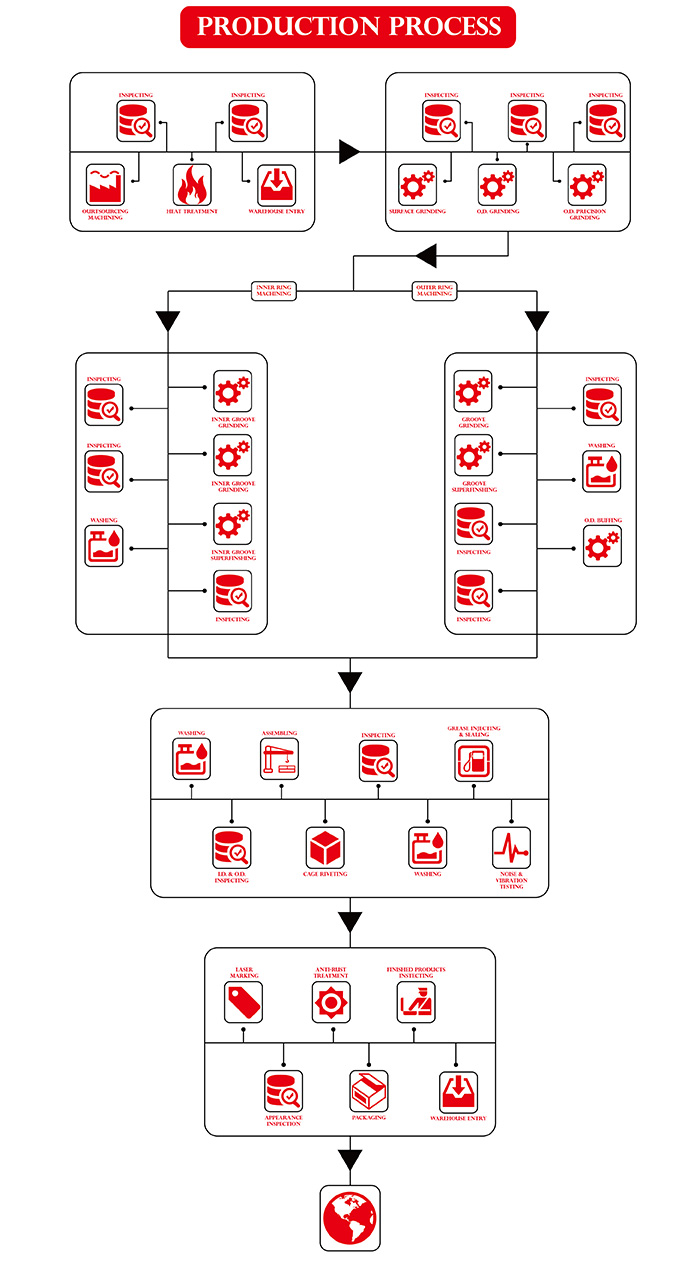

HOW TO MAKE PRODUCTION IN WM BEARING COMPANY?

Contact us if you need more details on High Speed Bearing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ceramic Bearing、Zirconia Ceramic Bearing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on High Speed Bearing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ceramic Bearing、Zirconia Ceramic Bearing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Features:

Features:1. Low density. As the rolling body density decreases, high-speed operation of its centrifugal load is also reduced, which can work at higher speed.

2. Moderate elastic modulus. Elastic modulus is too large due to stress concentration and reduce the bearing capacity of the bushing.

3. Thermal expansion coefficient is small. Reduce the sensitivity to temperature changes, so that the bearing operating temperature range is wider.

4. High compressive strength. High compressive strength is the need for high stress for rolling bearings.

5. High hardness and high toughness. These two properties combine to achieve better surface roughness; and can prevent external particles and shock damage.

6. Good anti-rolling contact fatigue and has a peel failure mode.

7. Special occasions should have high temperature, corrosion resistance and stability.

Applications:

The ceramic material has low density, medium elastic modulus, thermal expansion coefficient is small, high hardness, high temperature, corrosion resistance, non-magnetic, etc., to silicon nitride ceramic ball for the rolling body of Ceramic Ball Bearings can significantly improve the bearing contact fatigue life, Has greatly expanded the application of rolling bearings, has been widely used in a variety of high-precision, high-speed machine tools, automobiles, racing, subway, motor, aero engine, petrochemical machinery, metallurgical machinery and other fields

About us:

We're the professional manufacturer of Deep Groove Ball Bearings with 20 years' experience in China. We focus on producing good quality with high precision and low friction ball bearings. The product is designed to support customers in Agricultural, Distribution, Electrical, Fluid, Industrial Transmission, Material Handling, Textile Industry and etc. For many applications, WM standard bearing will meet customer performance expectations.

Delivery:

Sample Date : 3~7 days

Production Date : 30 days after receiving advanced payment.

Shipping : By express (TNT/ FedEx / DHL / EMS ) or By Sea

Payment Term: A. 30% T/T In Advance , 70% T/T paid against B/L copy at sight

B. 100% L/C at sight

Packing : Industrial Package or According to customer's requirement

SGS/CE/ISO9001 CERTIFICATE

| BEARING NO. | Dimension(mm) | Rated load(KN) | Max. Speed(rpm) | Weight | |||||

| d | D | B | Rsmin | Cr | Cor | Grease | Oil | (kg) | |

| 6300 | 10 | 35 | 11 | 0.6 | 5.88 | 3.47 | 20000 | 26000 | 0.054 |

| 6301 | 12 | 37 | 12 | 1.0 | 7.48 | 4.65 | 17000 | 22000 | 0.058 |

| 6302 | 15 | 42 | 13 | 1.0 | 8.80 | 5.43 | 16000 | 20000 | 0.082 |

| 6303 | 17 | 47 | 14 | 1.0 | 10.45 | 6.56 | 15000 | 19000 | 0.110 |

| 6304 | 20 | 52 | 15 | 1.1 | 12.26 | 7.81 | 13000 | 17000 | 0.140 |

| 6305 | 25 | 62 | 17 | 1.1 | 17.22 | 11.39 | 10000 | 14000 | 0.220 |

| 6306 | 30 | 72 | 19 | 1.1 | 20.77 | 14.17 | 9000 | 12000 | 0.330 |

| 6307 | 35 | 80 | 21 | 1.5 | 25.66 | 17.92 | 8000 | 10000 | 0.410 |

| 6308 | 40 | 90 | 23 | 1.5 | 31.35 | 22.38 | 7000 | 9000 | 0.600 |

| 6309 | 45 | 100 | 25 | 1.5 | 40.66 | 30.00 | 6300 | 7500 | 0.770 |

| 6310 | 50 | 110 | 27 | 2.0 | 47.58 | 35.71 | 6000 | 7000 | 1.030 |

| 6311 | 55 | 120 | 29 | 2.0 | 55.05 | 41.91 | 5600 | 6700 | 1.367 |

| 6312 | 60 | 130 | 31 | 2.1 | 62.88 | 48.60 | 5000 | 6000 | 1.710 |

| 6313 | 65 | 140 | 33 | 2.1 | 72.21 | 56.68 | 4500 | 5300 | 2.100 |

| 6314 | 70 | 150 | 35 | 2.1 | 80.10 | 63.48 | 4300 | 5000 | 2.550 |

| 6315 | 75 | 160 | 37 | 2.1 | 87.25 | 71.67 | 4000 | 4800 | 3.050 |

| 6316 | 80 | 170 | 39 | 2.1 | 94.57 | 80.35 | 3800 | 4500 | 3.610 |

| 6317 | 85 | 180 | 41 | 3.0 | 102.05 | 89.52 | 3600 | 4300 | 4.284 |

| 6318 | 90 | 190 | 43 | 3.0 | 110.81 | 100.76 | 3400 | 4000 | 4.97 |

HOW TO SATISFY CUSTOMERS?

HOW TO MAKE PRODUCTION IN WM BEARING COMPANY?

Contact us if you need more details on High Speed Bearing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ceramic Bearing、Zirconia Ceramic Bearing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on High Speed Bearing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ceramic Bearing、Zirconia Ceramic Bearing. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Ceramic Ball Bearings

Premium Related Products

Other Products

Hot Products

URC High-quality Pillow Block Ball BearingsURC Thrust deep groove ball bearingURC Professional Self-alinging ball bearingsURC Needle Roller BearingURC Professional Angular Contact Ball Bearings40*80*18mm 6208 Open Zz 2RS Deep Groove Ball BearingChina Bearings Manufacturers Cylindrical Roller BearingGalvanized W Beam Highway Guardrails2017 Newest 608 Free Sample Fidget Hand SpinnerChinese Manufacturer Needle Roller BearingSelf-Aligning Spherical Roller BearingsHigh Quality Chrome Steel Spherical Roller Bearing for Rotor PumpGcr15 One Way Thrust Ball Bearings⪞ Ompetitive Pri⪞ E Deep Groove Ball Bearing with ISO Certifi⪞ AteChik Auto Parts of Metric Taper Roller Bearing (30202)6309 High Temperature High Speed Hybrid Ceramic Ball Bearing